Cold rooms play a critical role in preserving perishable goods and maintaining food safety in various industries, including restaurants, grocery stores, and pharmaceutical facilities. However, like any mechanical system, cold rooms can experience malfunctions or breakdowns, especially during critical times. In this guide, we’ll discuss what to do when your cold room breaks down unexpectedly and how to handle emergency cold room repair situations effectively.

Assess the Situation:

The first step in dealing with an unexpected cold room breakdown is to assess the situation calmly and thoroughly. Determine the extent of the problem and identify any immediate safety hazards, such as temperature fluctuations, leaks, or unusual noises. Check the temperature inside the cold room and inspect the equipment, including compressors, condensers, evaporators, and controls, for any visible signs of damage or malfunction. Understanding the nature and severity of the issue will help you make informed decisions about the next steps and prioritize actions to minimize downtime and mitigate risks.

Contact a Professional Repair Service:

In an emergency cold room repair situation, it’s essential to contact a professional repair service as soon as possible. Look for a reputable and experienced cold room repair company with a track record of responding promptly to emergency calls and providing reliable repair services. Provide the repair service with detailed information about the problem, including the type of cold room, symptoms of the issue, and any relevant history or maintenance records. Be prepared to answer questions and follow any instructions provided by the repair service to expedite the repair process and minimize disruption to your operations.

Take Immediate Action to Preserve Perishable Goods:

While waiting for the repair service to arrive, take immediate action to preserve perishable goods stored in the cold room. If possible, transfer sensitive items to alternative cold storage facilities, such as backup cold rooms, walk-in refrigerators, or portable refrigeration units. Prioritize high-value or temperature-sensitive items and ensure they are stored at the appropriate temperature to prevent spoilage or contamination. If transferring items is not feasible, monitor the temperature inside the cold room closely and take steps to maintain it within safe limits until the repair service can address the issue.

Document the Incident:

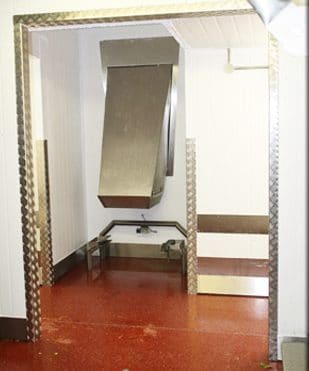

As part of your emergency response efforts, document the incident and keep detailed records of all actions taken during the cold room breakdown. Take photographs or videos of the affected equipment and surroundings to provide visual documentation of the problem. Keep track of the timeline of events, including when the issue occurred, when repair services were contacted, and any interim measures taken to mitigate the impact on operations. Documenting the incident will not only help you communicate effectively with the repair service but also provide valuable information for insurance claims or regulatory compliance purposes.

Communicate with Stakeholders:

During an emergency cold room repair situation, effective communication with stakeholders is crucial to ensure everyone is informed and aware of the situation. Keep key personnel, such as managers, supervisors, and maintenance staff, informed about the status of the cold room breakdown and any actions being taken to address it. Communicate with suppliers, customers, and other business partners to update them on any disruptions or delays in service resulting from the cold room breakdown. Transparency and proactive communication will help minimize the impact of the situation on your business relationships and reputation.

Follow Up After Repairs:

Once the emergency cold room repair is completed, follow up with the repair service to ensure that the issue has been fully resolved and that the cold room is operating safely and efficiently. Conduct thorough testing and monitoring of the cold room to verify that temperatures are stable and within the desired range. Address any remaining concerns or issues with the repair service promptly and document any follow-up actions taken. Additionally, consider scheduling regular maintenance inspections and preventive maintenance services to prevent future breakdowns and ensure the ongoing reliability of your cold room system.

Implement Preventive Measures:

After experiencing an emergency cold room repair situation, it’s essential to learn from the incident and implement preventive measures to reduce the likelihood of similar issues occurring in the future. Review the root causes of the breakdown with your repair service and identify any underlying issues or deficiencies in maintenance practices, equipment, or operations. Implement corrective actions, such as upgrading equipment, enhancing maintenance procedures, or providing staff training, to address identified weaknesses and improve the reliability and resilience of your cold room system.

Final Thoughts:

Dealing with an emergency cold room repair situation can be stressful and disruptive, but with the right approach and preparation, you can minimize the impact on your operations and ensure a swift and effective resolution. By assessing the situation promptly, contacting a professional repair service, taking immediate action to preserve perishable goods, documenting the incident, communicating with stakeholders, following up after repairs, and implementing preventive measures, businesses can navigate emergency cold room repair situations successfully and safeguard the integrity of their cold storage operations.